Onsite Health & Safety Training Courses

Read more

4 DIRECTIONAL REACH FORKLIFT COMBILIFT TRAINING CERTIFICATION - SAFE OPERATION

Read more

ADVANCED POWER PRESS ENTRAPMENT SAFETY AND RESCUE TRAINING CERTIFICATION

Read more

AERIAL BOOM LIFT (GENIE BOOM) TRAINING CERTIFICATION - SAFE OPERATION

Read more

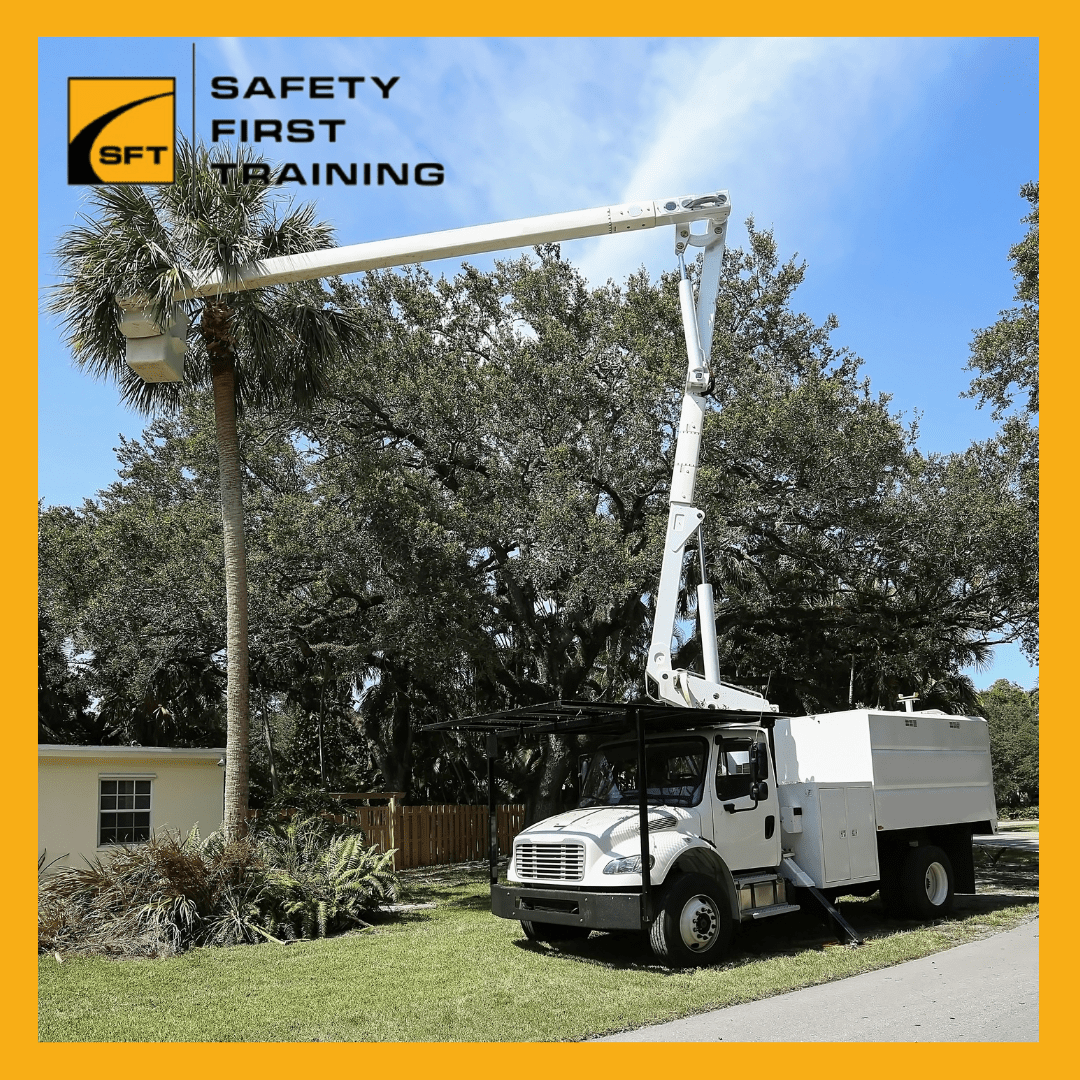

BUCKET TRUCK AERIAL LIFT TRAINING CERTIFICATION - SAFE OPERATION

Read more

CHAINSAW SAFETY TRAINING

Read more

COUNTERBALANCE FORKLIFT TRAINING CERTIFICATION - SAFE OPERATION

Read more

DOCK STOCKER TRAINING CERTIFICATION - SAFE OPERATION

Read more

ELECTRIC MOTORIZED PALLET JACK TRUCK TRAINING CERTIFICATION - SAFE OPERATION

Read more

ELEVATED WORK PLATFORM SAFETY TRAINING CERTIFICATION - SAFE OPERATION

Read more

HIGH CAPACITY FORKLIFT AKA HEAVY DUY FORKLIFT TRAINING CERTIFICATION - SAFE OPERATION

Read more

LADDER SAFETY TRAINING CERTIFICATION

Read more

ORDER PICKER SAFETY TRAINING CERTIFICATION - SAFE OPERATION

Read more

OVERHEAD CRANE TRAINING AND OPERATOR CERTIFICATION - SAFE OPERATION

Read more

POWER PRESS ENTRAPMENT AND HAZARD SAFETY TRAINING CERTIFICATION

Read more

REACH FORKLIFT OPERATOR TRAINING CERTIFICATION - SAFE OPERATION

Read more

SCISSOR LIFT AERIAL LIFT TRAINING CERTIFICATION - SAFE OPERATION

Read more

SKID STEER BOBCAT SAFETY TRAINING CERTIFICATION - SAFE OPERATION

Read more

STAND UP REACH FORKLIFRT TRAININ AND CERTIFICATION

Read more

SWING REACH TURRET TRUCK TRAINING CERTIFICATION - SAFE OPERATION

Read more

TELEHANDLER TRAINING CERTIFICATION - SAFE OPERATION

Read more

TRUCK MOUNTED FORKLIFT TRAINING CERTIFICATION - SAFE OPERATION

Read more

TUGGER TRAINING CERTIFICATION

Read more

WALKIE RIDER PALLET JACK TRAINING CERTIFICATION - SAFE OPERATION

Read more

WORKING AT HEIGHTS FULL TRAINING - CPO WAH TRAINING APPROVED

Read more