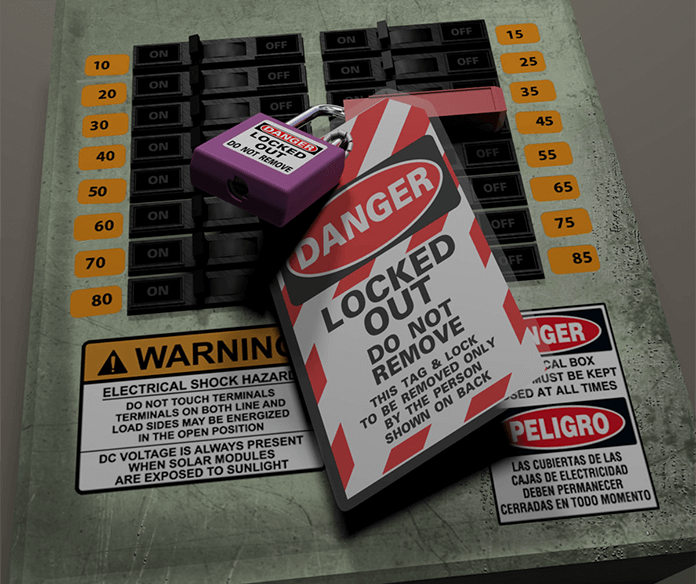

Lockout Tagout Safety Training

Lockout tagout safety training is important because it prevents injuries and saves lives. However, a lot of companies do not offer lockout tagout safety training.

Many companies refrain from offering lockout/tagout safety training to their employees since it would necessitate those workers learning new skills and taking time away from their workday.

However, there are many benefits to offering lockout/tagout safety trainings including:

- Increased productivity

- Reduced employee turnover

- Improved customer service

- Decreased insurance costs

- Better retention rates

- Higher morale

- Lower absenteeism

- Fewer accidents

- More satisfied customers

- Less downtime

Who Should Take Lockout / Tagout Safety Training?

Anyone working with power tools or machinery should know how to properly lockout and tagout equipment before performing work. You never know when someone might accidentally touch the wrong part of the machine and cause injury.

This training course teaches you how to safely perform lockout/tagout procedures. You’ll learn how to identify hazards, prevent injuries, and follow proper safety protocols.

Topics covered include:

- Identifying Hazards

- Preventing Injury

- Following Proper Procedures

- How to Perform Lockout/Tagout Procedures

- What to Do After Lockout/Tagout Procedure

- Who Should Attend

- Definitions and standards

- What is lockout/tagout?

- Different types of energy

- Energy control plans

- Safe work practices

- Common hazards

This course is ideal for anyone who works with power tools or machinery. Whether you’re a professional mechanic, contractor, or hobbyist, you’ll find this training course helpful.

What Does Lockout Tag Out Training Entail?

LOTO stands for lockout/tag out. It’s a safety procedure used to prevent injuries caused by hazardous energy sources. You can find out more about how to implement LOTO here.

In order to have a successful hazard control program, it needs to include the process of identifying hazards, implementing and training on lockouts and tag outs, and retraining employees to maintain proficiency.

Training is a key element in developing a successful hazard control program. This training should include the process of identifying potential hazards, implementing and training employees on lockouts and tagouts, and retraining employees if necessary.

A lockout/tagout program will be most effective if it covers the following three areas:

- Identifying Hazards – What does your company produce that poses a risk to workers? Are there any chemicals or gases that may cause harm? Is there anything else that might present a danger?

- Implementing Lockouts and Tag Outs – How do you protect yourself from harmful substances? Do you know where to turn off power to machines? Can you safely shut down equipment?

- Retraining Employees – How do you keep employees safe? Do you provide refresher courses? Do you train new hires?

Lockout/tagout safety training is a requirement on every job site. The purpose of the training is to help stop accidents from happening by making sure that all workers are properly taught and have the necessary equipment to deal with hazardous conditions. after reading this article, you should now understand why it’s so important for all employees to receive lockout/tagout safety training.

Click here for Lockout Tagout Safety Training

Click here for Government of Canada Lockout Tagout Information

Recent Blogs

- Propane Training for CH-02 Heaters and CH-02T Torches

- National Day of Mourning - April 28

- WHMIS Training in Richmond Hill

- Fire Safety Training Etobicoke

- FIRST AID & CPR TRAINING

- Aerial Lift Facts

- Why CMRAO Requires CPE Credits for Condo Managers & How to Earn Them

- WHMIS Training and Certification in Pickering

- Forklift Use in the Workplace

- WHMIS Training Certification in Brampton

- WHMIS Training and Certification in Markham

- Industrial Lift Equipment Training

- Online Safety Training

- Counterbalance Forklift Training Whitby

- WHMIS Certification in Vaughn

- Counterbalance Forklift Training in Ontario: Boost Safety and Compliance with Safety First Training

- Transportation of Dangerous Goods

- Scissor Lift and Genie Boom Training In Toronto

- Scissor Lift Training and Certification for Safe Operations

- Air Quality a Main Reason for Respirator Mask Fit Testing